Chain Sling Parts: Essential Components and Hardware for Safe Lifting Operations

Modern overhead lifting operations depend on precision-engineered chain sling parts that meet demanding safety and performance standards. These sophisticated assemblies represent over a century of metallurgical advancement, transforming from simple weldless chains into today’s rigorously tested, alloy steel systems. Understanding the technology, specifications, and proper selection of chain sling components is essential for safe lifting operations across construction, manufacturing, and industrial applications.

Key Takeaways

-

Master links (oblong links) serve as the primary connection point for multi-leg chain slings

-

Lifting chains in Grade 80, Grade 100, and Grade 120 form the backbone of chain sling assemblies

-

Hooks including grab hooks, foundry hooks, and self-locking hooks provide secure load attachment

-

Connecting links and adjusters enable customization and length modification of chain slings

-

Identification tags are mandatory for all overhead lifting chain slings per ASME B30.9 standards

-

Proper selection of chain sling parts ensures working load limits and safety compliance

Essential Chain Sling Components

A complete chain sling assembly consists of several specialized components, each engineered to meet specific safety and performance requirements. These sling parts work together to create a reliable connection between lifting equipment and loads, with each component contributing to the overall working load limit and safety profile of the system.

The primary components include the identification tag, upper end fittings (typically master links), lifting chain legs, and lower end fittings (usually hooks). Additional rigging hardware such as connecting links and adjusters may be incorporated for customization or field modifications. All components must be manufactured from compatible alloy steel grades and meet precise dimensional tolerances for overhead lifting applications.

Material grade selection directly impacts component compatibility and overall assembly strength. Grade 80 represents the minimum standard for overhead lifting, while Grade 100 has become the industry standard due to its 25% strength advantage. Grade 120 chain offers premium performance with up to 50% higher strength than Grade 80, enabling lighter slings for equivalent load capacities.

Working load limit calculations depend on the weakest component in the assembly and must account for factors such as sling angle, temperature exposure, and load distribution. Proper component selection ensures compliance with ASME B30.9 standards and maintains the safety factors required for industrial lifting operations.

Master Links and Upper End Fittings

Master links serve as the critical connection point between chain slings and lifting equipment, making them one of the most important chain sling parts in any assembly. The oblong master link is the industry standard for multi-leg configurations due to its superior load distribution characteristics and ability to accommodate multiple chain legs without overcrowding.

Oblong (oval-shaped) master links distribute stress evenly across their curved surfaces, especially when multiple legs are under tension. This design minimizes stress concentrations that could lead to premature failure in demanding lifting applications. Round and pear-shaped collector rings are available for specialized applications where standard oblong links may not be suitable.

For triple-leg and quadruple-leg assemblies, oversized master links with sublinks provide adequate spacing between chain legs. This configuration prevents interference between legs and ensures proper load alignment during lifting operations. The additional space also facilitates inspection and maintenance of individual components.

Connection methods vary based on application requirements. Direct welding provides permanent attachment but limits field modifications. Mechanical connectors such as clevis or hammerlock couplers offer removable connections for applications requiring component replacement or reconfiguration.

Size and grade specifications for master links must match the lifting chain grade and diameter. Grade 100 master links provide 25% higher working load limits compared to Grade 80 for equivalent sizes, while Grade 120 offers up to 50% strength increase. All master links must meet ASTM A952/A952M specifications and comply with ASME B30.9 requirements for dimensional tolerances and proof testing.

Lifting Chain Types and Grades

Lifting chains form the tensile backbone of chain sling assemblies, with their grade and diameter determining the fundamental strength characteristics of the complete sling. Modern alloy chain slings are manufactured from precisely controlled steel compositions and undergo specialized heat treatment processes to achieve the mechanical properties required for safe overhead lifting.

Grade 80 alloy chain represents the minimum standard for overhead lifting applications in North America and Europe. Manufactured from tempered alloy steel with boron treatment or nickel-chromium alloying, Grade 80 chain provides adequate strength for basic lifting operations. However, its use is increasingly limited to legacy systems or cost-sensitive applications where higher grades are not specified.

Grade 100 chain has emerged as the global industry standard due to its superior strength-to-weight ratio and enhanced fatigue resistance. The 25% strength increase over Grade 80 enables the use of smaller chain diameters for equivalent working load limits, improving sling ergonomics and reducing handling difficulties. Grade 100 chains are manufactured from higher-alloy steels with optimized heat treatment cycles.

Grade 120 chain represents premium performance in lifting chain technology. Its unique square or quad link profile, compared to the round links of Grades 80 and 100, provides up to 50% higher strength than Grade 80. This metallurgical advancement allows for significantly lighter slings while maintaining equivalent load capacities, addressing ergonomic concerns in heavy-duty applications.

Standard chain diameters range from 1/4 inch (6 mm) to approximately 1 inch (26 mm), with working load limits spanning from 3,500 pounds to over 35,000 pounds depending on grade and configuration. The relationship between chain diameter and grade directly determines maximum safe lifting capacity, making proper specification critical for compliance and safety.

Heat treatment processes including quenching and tempering optimize both tensile strength and ductility in lifting chains. Chemical composition and microstructure are tightly controlled to prevent brittle failure modes that could result in catastrophic load drops. Each chain grade must meet specific elongation and impact resistance criteria in addition to tensile strength requirements.

Hook Types and Lower End Fittings

End fittings provide the crucial load attachment points in chain sling assemblies, with hook selection depending on application requirements, safety considerations, and load characteristics. These components must combine mechanical strength with operational functionality while maintaining compatibility with lifting chain grades and working load limits.

Grab hooks feature narrow throats designed to capture or “grab” individual chain links, enabling length adjustment by repositioning the hook along the chain. This adjustable chain capability makes grab hooks ideal for applications requiring variable sling lengths or fine-tuning of load balance between multiple legs. The hook design must accommodate the specific chain diameter and grade being used.

Foundry hooks are engineered for high temperature environments such as steel mills and foundries. Their extra-wide, open throat design facilitates quick load engagement and release in demanding industrial conditions. The wider opening also accommodates larger lifting lugs and provides clearance for operations requiring rapid hook positioning.

Sling hooks serve as general-purpose end fittings with wide throats for secure attachment to lifting lugs and engineered attachment points. Many sling hook designs incorporate safety latches to prevent accidental disengagement during lifting operations. The latch mechanism must be regularly inspected to ensure proper function and compliance with safety standards.

Self locking hooks automatically close and lock under load, providing enhanced safety for applications where load drop could result in catastrophic consequences. The automatic closure mechanism eliminates reliance on operator action to secure the load connection, reducing human error risks in critical lifting operations.

Clevis hooks attach to sling assemblies via mechanical pins (clevis connections), providing strong, easily replaceable connections suitable for rugged environments. This design facilitates quick hook changes when different hook types are required for varying load configurations or when hooks require replacement due to wear.

Eye hooks are designed for permanent attachment through master links or connecting hardware, typically used where swiveling capability is not required. Their fixed orientation makes them suitable for applications with consistent load attachment points and predictable load orientations.

Selection criteria for hooks must consider not only mechanical strength but also safety features, application-specific requirements, and regulatory compliance for latching mechanisms. All hooks must be manufactured from alloy steel grades compatible with the lifting chain and must meet the same working load limit requirements as other sling components.

Connecting Hardware and Accessories

Specialized connecting hardware enables flexibility, customization, and field modifications in chain sling assemblies. These accessories allow riggers to adapt standard slings for specific applications while maintaining compliance with safety standards and working load limit requirements.

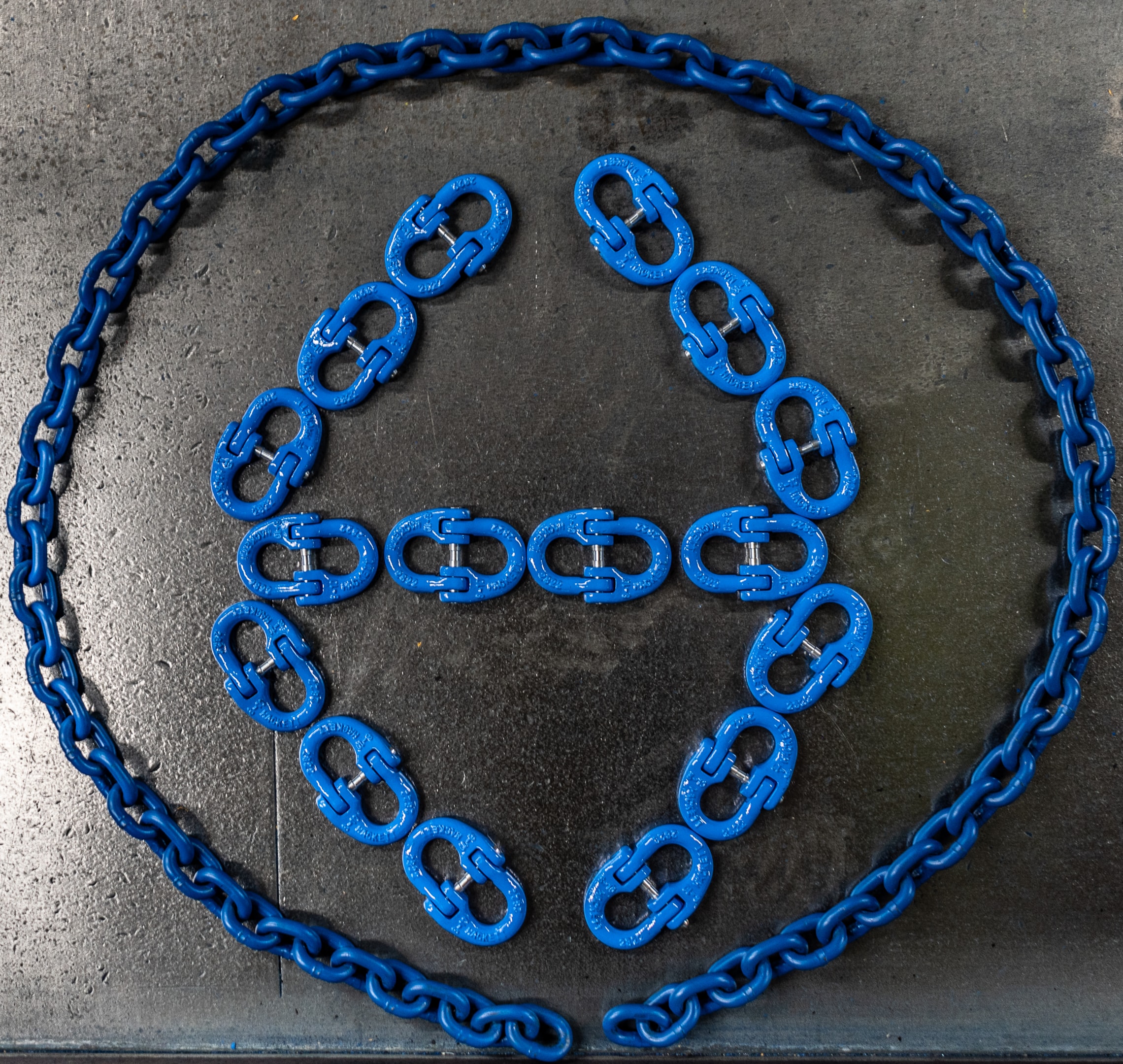

Connecting links, including butterfly buckles and hammerlock connectors, provide secure joints between chains, rings, and hooks. These forged alloy steel components must meet the same grade and strength requirements as the primary sling components. Proper installation requires attention to orientation and securing mechanisms to prevent accidental disconnection under load.

Double ring buckles offer flexible connection options in rigging systems, allowing multiple attachment points or load distribution modifications. These accessories are particularly useful in complex lifting operations where standard single-point attachments are insufficient for load control or stability.

Chain shorteners and adjusters enable modification of sling leg lengths without permanent alterations to the assembly. This adjustable functionality is critical for multi-leg operations where load balance between legs must be fine-tuned for safe lifting. Adjusters must be rated for the full working load limit of the sling assembly.

Repair links facilitate field maintenance and emergency repairs when primary components become damaged or worn. However, repair links must meet identical grade and strength specifications as original components, and their use may require re-certification of the complete assembly working load limit.

Shackles provide removable, articulated connections for applications requiring oversized lugs or non-standard attachment points. All shackles used in chain sling assemblies must be load-rated and properly sized to avoid becoming the limiting factor in assembly strength. Pin retention and proper torque specifications are critical for safe shackle operation.

The selection and installation of connecting hardware requires careful consideration of load paths, stress concentrations, and compatibility with existing sling components. Improper hardware selection or installation can significantly reduce assembly working load limits and create safety hazards.

Identification Tags and Compliance

Identification tags represent a critical compliance requirement for all overhead lifting chain slings, serving as permanent documentation of assembly specifications, working load limits, and regulatory compliance. ASME B30.9 standards mandate that identification tags remain attached throughout the service life of chain sling assemblies.

Required tag information includes manufacturer identification, unique serial numbers, chain grade and size specifications, working load limits by configuration and angle, number of legs, manufacture date, proof test documentation, and compliance indicators for ASME, NACM, ASTM, and OSHA standards. This data enables proper sling selection, load limit verification, and traceability for safety audits.

Tag construction typically utilizes stainless steel or heavy-gauge aluminum materials to resist damage in industrial environments. Attachment methods must ensure tags cannot be accidentally removed or damaged during normal sling operations. Laser etching or deep stamping provides permanent marking that resists wear and environmental exposure.

Working load limit information must account for different sling configurations and angles. Single-leg vertical lifts provide maximum capacity, while multi-leg assemblies at various angles require load reduction factors. Tag data must clearly indicate these derating factors to prevent overloading.

Missing or illegible identification tags immediately place chain slings out of service until proper tags are installed. Replacement procedures typically require complete re-verification of assembly components, including proof testing to document compliance with original specifications. This requirement emphasizes the importance of tag protection during sling operations and storage.

Compliance documentation extends beyond tags to include manufacturer certificates, proof test records, and inspection logs. These documents provide the traceability required for regulatory compliance and support safety auditing processes in industrial facilities.

Chain Sling Assembly Configurations

Chain sling assemblies are classified by the number of legs and hardware arrangements, with each configuration optimized for specific lifting applications and load characteristics. Understanding these configurations is essential for proper sling selection and safe rigging practices.

Single leg slings represent the simplest configuration, featuring a master link, single chain leg, and terminal hook. These assemblies are versatile and can be used in vertical, choker, or basket hitch configurations. Single leg assemblies provide maximum working load limit when used in straight vertical lifts but require load reduction when used at angles.

Double-leg slings feature an oblong master link with two chain legs terminating in hooks. This configuration provides improved load stability and balance compared to single-leg assemblies. The dual legs help prevent load rotation and provide redundancy if one leg becomes damaged, though both legs must be designed for the full load.

Triple-leg and quadruple-leg assemblies utilize specialized master links with adequate spacing for three or four chain legs. These bridle configurations are designed for complex, large, or off-centered loads where improved load control is essential. The multiple attachment points distribute loads more evenly and reduce stress concentrations at individual lifting points.

Assemblies can be manufactured as fixed-length or adjustable configurations. Adjustable chain slings incorporate grab hooks or chain shorteners that allow rapid length changes to accommodate different loads or sling angles. This flexibility reduces the inventory of slings required for varied lifting operations.

Custom assemblies may incorporate specialized hardware, intermediate rings, or legs of different lengths for unique lifting requirements. These configurations require careful engineering analysis to ensure proper load distribution and compliance with safety standards.

Sling Designation Codes

The industry utilizes standardized three-letter acronym systems to efficiently describe sling configurations for ordering, inspection, and documentation purposes. This coding system provides clear communication between manufacturers, suppliers, and end users.

The first letter indicates the number of legs: S for single leg, D for double leg, T for triple leg, and Q for quadruple leg configurations. This designation immediately identifies the basic sling architecture and complexity.

The second letter specifies the upper end fitting type, with O representing oblong master links and S indicating sling hook configurations. The upper fitting type affects load distribution and attachment methods to lifting equipment.

The third letter describes the lower end fitting type: G for grab hooks, S for sling hooks, F for foundry hooks, and other letters for specialized hook types. Lower fitting selection depends on load attachment requirements and environmental conditions.

Optional fourth letters may indicate special features such as adjusters (A), custom configurations, or environmental protection measures. These designations help specify non-standard features that affect sling performance or application suitability.

Common designation examples include DOS (Double leg, Oblong master link, Sling hooks) and SOG (Single leg, Oblong master link, Grab hook). This standardized system facilitates accurate ordering and reduces confusion in sling specification.

Material Specifications and Quality Standards

Chain sling parts must meet rigorous material specifications and quality standards to ensure safe performance in overhead lifting applications. These requirements encompass alloy composition, heat treatment processes, dimensional tolerances, and testing protocols that verify component integrity.

Alloy steel composition for lifting chains and hardware is precisely controlled according to ASME, ASTM, and NACM standards. Specific alloying elements including chromium, nickel, boron, and molybdenum are added in controlled amounts to achieve the strength, ductility, and fatigue resistance required for lifting applications. Carbon content is tightly regulated to prevent brittleness while maintaining adequate strength.

Heat treatment processes utilize carefully controlled quenching and tempering cycles to optimize microstructure and mechanical properties. Each component must achieve specific tensile strength, yield strength, and elongation values while maintaining impact resistance. The heat treatment process is critical for developing the combination of strength and toughness required for safe lifting operations.

Quality standards compliance requires adherence to multiple industry standards. ASME B30.9 establishes sling safety and performance requirements, while ASTM A952/A952M covers welded and mechanical chain sling assemblies. OSHA 1910.184 provides regulatory requirements for chain sling use in the United States, and NACM standards govern chain manufacturing practices.

Proof testing requirements mandate that assemblies withstand loads of at least twice the rated working load limit without permanent deformation or failure. Individual chains must meet specific burst load criteria with controlled elongation limits. These tests verify that safety factors are maintained throughout the load range.

Breaking strength minimums and safety factor calculations ensure adequate margins between working loads and ultimate failure. Typical safety factors range from 4:1 to 5:1, meaning components must withstand four to five times the working load limit before failure. These margins account for dynamic loading, wear, and environmental factors that may affect component strength over time.

Fatigue testing data provides insight into service life expectations under repeated loading cycles. While actual service life depends on usage patterns, environment, and maintenance practices, fatigue test results help establish inspection intervals and replacement criteria for chain sling parts.

Installation and Assembly Guidelines

Proper installation and assembly of chain sling parts requires adherence to manufacturer specifications and industry best practices to ensure safe operation and regulatory compliance. These procedures directly affect the working load limit and safety performance of completed assemblies.

Assembly procedures must ensure all components match in grade, size, and specifications. Mixing different grades within a single assembly is prohibited as it creates unpredictable failure modes and compromises traceability. Component compatibility verification includes checking chain diameter, hook throat opening, and master link capacity.

Connecting hardware installation requires attention to proper orientation, pin retention, and torque specifications. Clevis pins must be properly secured with retaining hardware, and hammerlock connectors must be oriented to prevent accidental opening under load. Torque specifications for threaded connections must be followed to ensure adequate clamping force without component damage.

Quality control checkpoints during assembly include visual inspection of all components, verification of proper fit and orientation, and documentation of component lot numbers. Any signs of damage, excessive wear, or dimensional discrepancies must be addressed before assembly completion.

Testing procedures before service placement typically include proof loading at twice the working load limit to verify assembly integrity. This test confirms that all connections are properly made and that the assembly can safely handle rated loads. Load testing must be conducted with properly calibrated equipment and documented for compliance records.

Documentation requirements for custom assemblies include detailed component specifications, assembly procedures, test results, and inspector identification. This documentation provides traceability for future inspections and supports regulatory compliance auditing.

Maintenance and Inspection of Chain Sling Parts

Regular maintenance and inspection of chain sling parts is essential for safe operation and regulatory compliance. These procedures help identify wear, damage, or deterioration before they compromise lifting safety or result in equipment failure.

Daily visual inspection procedures must be performed before each use and should include examination of all sling components for signs of damage, wear, or deformation. Chains must be checked for link elongation, surface wear, gouging, or cracks. Any chain showing 10% wear in cross-sectional area or visible cracking must be immediately removed from service.

Detailed inspection criteria for hooks and connecting hardware includes checking for tip opening beyond manufacturer specifications, latch integrity, and evidence of lateral deformation. Hook tips that have opened beyond safe limits indicate overloading or impact damage that compromises load retention capability.

Signs requiring immediate removal from service include any visible cracks, excessive wear exceeding manufacturer limits, significant corrosion that reduces cross-sectional area, or deformation that affects component geometry. OSHA and manufacturer criteria specify maximum allowable dimensional changes and deformation limits.

Cleaning and lubrication recommendations help prevent internal corrosion and extend service life. Cleaning methods depend on environmental contamination but typically involve solvent or water-based cleaning followed by approved lubricants. High temperature environments may require specialized lubricants that maintain properties under thermal exposure.

Record keeping requirements include inspection logs, maintenance actions, component replacements, and any repairs performed. These records support regulatory compliance and enable trending analysis to optimize replacement intervals and identify potential problems before they result in failures.

Replacement criteria must consider not only individual component condition but also overall assembly integrity. When any component is replaced, the working load limit of the complete assembly must be recalculated based on the weakest component, accounting for any derating factors.

Safety Considerations and Best Practices

Working load limit calculations form the foundation of safe chain sling operations and must account for sling configuration, load angle, and environmental factors. The relationship between sling angle and leg loading is critical - as the angle between legs decreases, the load on each leg increases significantly, potentially exceeding safe limits.

Temperature limitations require load reduction factors when chain slings are used in high temperature environments such as foundries or steel mills. Heat exposure weakens the microstructure of alloy steel and can permanently reduce component strength. Manufacturer derating tables provide specific load reduction requirements based on temperature exposure duration and intensity.

Edge protection requirements become critical when lifting loads with sharp corners or abrasive surfaces that could damage chain links. Edge protectors, sleeves, or synthetic padding help prevent premature chain failure due to cutting or excessive wear. The protection method must be suitable for the load weight and environmental conditions.

Proper storage methods prevent corrosion and damage during periods of non-use. Chain slings should be hung in dry locations away from corrosive environments and never stored in contact with the ground. Regular inspection of stored slings helps identify hidden corrosion or damage that might not be apparent during routine use.

Training requirements for personnel handling chain sling assemblies must include formal rigging and sling safety instruction in accordance with company policies and regulatory requirements. Operators must understand load limits, proper rigging techniques, and inspection procedures to ensure safe operations.

Emergency procedures must be established and regularly practiced for events such as load drops, component failure, or sling entanglement. Clear protocols help minimize injury risks and property damage while ensuring rapid response to potentially dangerous situations.

FAQ

What is the difference between Grade 80, Grade 100, and Grade 120 chain sling parts?

Grade 80 represents the minimum standard for overhead lifting with basic strength characteristics. Grade 100 offers 25% higher strength than Grade 80 and has become the industry standard due to improved fatigue resistance. Grade 120 provides up to 50% higher strength than Grade 80 and often features a square link profile for maximum performance. Grades cannot be mixed within a single sling assembly.

How do I determine the correct master link size for my chain sling assembly?

Master link sizing depends on the number of sling legs, chain diameter, hook opening requirements, and grade specifications. Manufacturers provide sizing charts that correlate minimum master link dimensions to these requirements. The master link must match or exceed the working load limit of the complete assembly and provide adequate space for all chain legs without interference.

Can I mix different grades of chain and hardware in a single sling assembly?

No, mixing different grades within a single assembly is prohibited. All components must be uniformly manufactured from the same material grade to ensure consistent strength characteristics, predictable failure modes, and proper traceability. Mixed-grade assemblies cannot be properly certified and create safety hazards.

What type of hook should I choose for my specific lifting application?

Hook selection depends on load characteristics, adjustment requirements, safety features needed, and environmental conditions. Grab hooks provide length adjustability, foundry hooks handle high-temperature applications, sling hooks offer general-purpose capability, and self locking hooks provide enhanced safety through automatic closure mechanisms.

How often should chain sling parts be inspected and replaced?

OSHA and ASME standards require daily visual inspections before each use and detailed periodic inspections at least annually for normal service conditions. High-frequency or abusive service may require more frequent detailed inspections. Components must be immediately removed when they show signs of excessive wear, damage, or deformation exceeding manufacturer limits.

Are chain sling parts interchangeable between different manufacturers?

Interchangeability between manufacturers is generally not recommended unless expressly approved in writing and confirmed through proof testing. Differences in steel composition, manufacturing tolerances, and design standards can result in non-uniform strength characteristics or unexpected failure modes.

What documentation is required when purchasing replacement chain sling components?

Replacement components require identification tag data, proof of compliance with applicable grade and specification standards, test certification documentation, and for critical applications, lot traceability back to manufacturer quality records. This documentation ensures proper component selection and supports compliance auditing.

How do I calculate the working load limit when replacing individual sling parts?

When any component is replaced, the working load limit must be recalculated based on the weakest component in the modified assembly. This calculation must include derating factors for geometry, temperature exposure, or wear conditions as specified by standards and manufacturer documentation. Professional engineering review may be required for complex modifications.

Chain sling parts represent critical components in modern lifting operations, requiring careful selection, proper maintenance, and strict adherence to safety standards. Understanding the specifications, applications, and regulatory requirements for these components ensures safe, compliant lifting operations across diverse industrial applications. Proper component selection, combined with regular inspection and maintenance, provides the foundation for reliable overhead lifting systems that protect personnel, equipment, and cargo in demanding industrial environments.